Overhead Crane

- Home

- Overhead Crane

Amaze Forklift Training

Overhead Crane

An Overhead crane is a machine that allows you to lift a piece of material or goods and move it from one location to another, using precise motion without the need to maneuver around. These are commonly used in factories, warehouses, shipyards, etc., to facilitate the lifting and movement of heavy objects within the area covered by the crane’s area of operation. Three primary types of cranes are used in industrial settings- Bridge Cranes, Gantry Cranes and Jib Cranes.

These machines are massive and can cause considerable damage if mishandled or used negligently. Therefore, the operators must be aware of the hazards arising from unsafe practices. Overhead Crane Training Program helps them learn proper crane and load handling procedures and preventive measures to maximize workplace safety. This CSA and OSHA-approved course covers industry-standard information and enables the workers to become certified Overhead Crane Operators. Organizations that impose training mandates at their facilities experience reduced downtime, higher job satisfaction, protection from liability-inducing lawsuits and effective prevention of workplace accidents.

Duration

Up to 2-4 hours, depending on participants’ experience levels

Assessment

A passing grade of 75% is required in order to receive a certificate”.

Completion

Upon successful completion of this course, participants will receive a PDF wall certificate and PDF wallet card for their records.

Still Confused About Our Features? Get A Consultation

Amaze Forklift Training

Course Content

- Basics of the course

- Relevant laws and guidelines

- Video Presentations

- Responsibilities of employers, supervisors and workers (Working on or around the equipment)

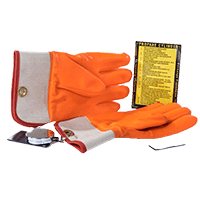

- Pre-use inspection of the equipment

- Safe operation of overhead cranes (including bridge, gantry, jib, and monorail cranes).

- General safety rules and incident prevention

- Load and lift capacity

- Basic rigging procedures

- Crane controls

- Load swing control

- Emergency stop signals

- Hazard Identification and Prevention

- Emergency Response

- Operator evaluation