Pallet Walkie Rider

- Home

- Pallet Walkie Rider

Amaze Forklift Training

Pallet Walkie Training

A pallet truck provides heavy-duty operation in warehouses, storage, distribution centres, etc. This machine allows the movement of materials in horizontal transport applications but does not necessarily lift them vertically. Whether the distance you need to move your load is long or short, it offers highly maneuverable and reliable solutions to help increase productivity. You may choose a walk-only version suitable for moving materials short distances. These applications may include organizing staging areas and racks, prepping loads for outbound ships etc. For longer distances- you may choose a ride-on model, which takes the manual labour out of moving a load.

Operators must be trained to understand the hazards to which they are exposed. Amaze Forklift has put together a Double Pallet Walkie Rider Training Program that will surely cover all the pallet walkie-rider training requirements, as stipulated by OSHA. This program is suitable for a novice as well as an experienced trainer. Our experts provide 1-on-1 guidance to help you complete the course within a few hours, depending on past knowledge and comprehension.

Duration

Up to 2-4 hours, depending on the participants’ experience levels.

Assessment

A passing grade of 80% is required in order to receive a pallet walkie rider training certificate.

Completion

Upon successful completion of this course, participants will receive a plastic wallet card for records.

Get your team trained to keep your workplace accident free

Amaze Forklift Training

What does Pallet Walkie Training program cover?

- Introduction to the course

- Relevant laws and guidelines

- Multimedia presentations

- Responsibilities of employers, supervisors and workers (Working on or around the equipment)

- Understanding of the general safety regulations

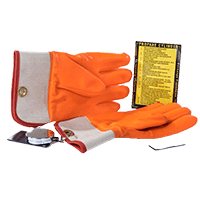

- Pre-use inspection procedures

- Preventive maintenance procedures

- Operating procedures- circle check, startup, shutdown, forward/reverse on level ground, parking)

- Identification and prevention of hazards

- Load limit and lift capacity

- Propane and battery handling

- Theoretical and practical assessment